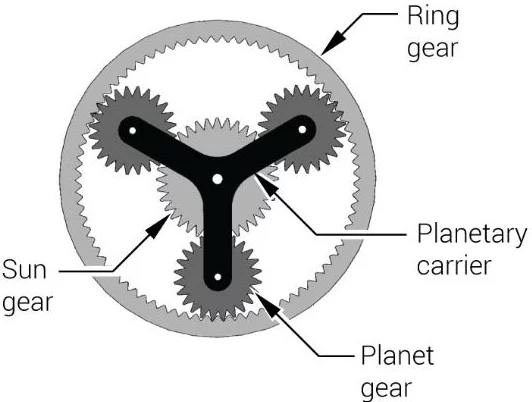

Sun Planet Gear

Components of a planetary gear

Sun gear

Ring gear

Planet gear

Planetary carrier

Introduction

Planetary Gears

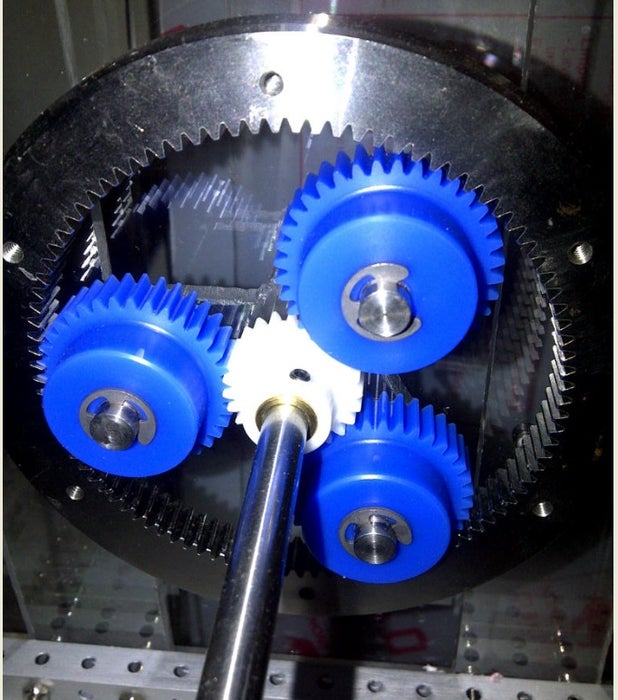

Planetary gears are also referred to as epicyclic gear trains. They contain an input and an output shaft in a coaxial arrangement. They consist of a number of gear wheels arranged around a central gear. Since this arrangement is reminiscent of planets orbiting the sun, the central wheel is also referred to as the sun gear, while the surrounding ones are called planet gears. They are located within an external gear ring. The sun gear is driven by a motor and transmits its motion to the surrounding planet gears, which roll against the surrounding gear ring and thus orbit the sun gear evenly. The planet gears are mounted on a joint carrier that is connected to the output shaft. The rotational speed of the output is lower than that of the drive, and the torque of the output is higher in reverse proportion. The more gear wheels mesh with each other, the higher the torque. In general, one planetary gear system contains three to four planet gears.

Planetary gears commonly comprise a combination of several gear wheels toggled within and behind each other, on the basis of this simple basic form. Several simple planet gear sets can be merged into a multiple gear unit. This enables a hub gear changer in a bicycle to have in excess of the three speeds usually achieved with a simple gear set.

“We are a leading specialist in the power transmission industry, please feel free to contact us regarding any planetary gearbox requirements. We have the in-house capability to adapt to all your requirements.”

Advantage

Advantages of planetary gear

High efficiency

High torque transmission capacity

Compact construction

Power transmission efficiency is very good

High power density

R & D experience

Exporting country

Designed product

A Trusted Gear Transmission Company

Operating modes of planetary gears

“We design, select and supply a wide range of high quality products including bespoke solutions tailored to your unique application.“

As a rule, a planetary gear comprises three shafts – the sun gear, the planet carrier, and the external ring gear. Often, though, the motion of one of the shafts is arrested, so that the input and output are on the other shafts. Which shaft or wheel is held, which serves as the input and which as the output depends on the constructive tasks. In certain cases, three-shaft operation is also used, in which either two shafts are driven and one is the driver (summation gears) or vice versa (distribution gears). Temporary three-shaft operation is also possible. Here, the third shaft is fixed by a frictional coupling. Under load, two-shaft operation can be interrupted and then restored by uncoupling and coupling.